Detailed Product Description

Technical Specifications

Quantitatively inspect internal and external flaws, including fatigue.

Correctly evaluate wire rope residual bearing capacity and service life

I. Introduction of URNDT-BX Portable Wire Rope Testers

URNDT-BX portable wire rope testers adopt patented Weak Magnetism inspection technology and have been recognized as the solution to the problems of “Hidden Dangers, Waste, and Low efficiency” of wire rope use. This equipment is able to correctly evaluate the residual carrying capacity and service life of in-service wire ropes by quantitatively detecting both internal and external flaws such as broken wires, corrosion, abrasion and fatigue. With this technical breakthrough in NDT technology, it is possible for the first time in the world to scientifically evaluate in-service wire rope’s residual bearing capacity, safety coefficient, and service life.

URNDT portable rope testers weigh only 2 KG, about 1/6~1/25 of the weight of conventional NDT testers. The sensitivity of URNDT Dou sensors could reach 5 V/G and the accuracy for evaluating the percentage loss of effective bearing metallic cross-sectional area is above 99.5%. It is also easy to operate, with unique auto-unlocking device and friendly interface designs.

When an inspection is completed, URNDT rope testers are able to display on the LCD screen testing data, flaw graph, data table, and test report. After connecting to a computer and printer, a formal test report could be printed, which provides scientific reference for users to use wire ropes more safely and replace wire rope more appropriately.

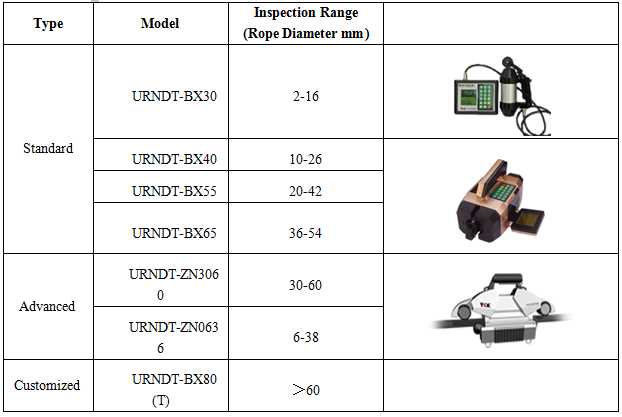

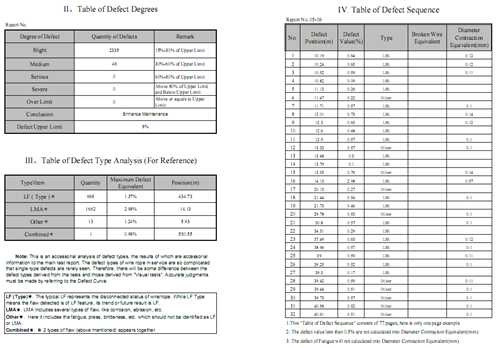

II. Models and Inspecting Range

III. Inspection Process

IV. Technical Specifications

1. Inspection technology: weak magnetism inspection technology;

IV. Technical Specifications

1. Inspection technology: weak magnetism inspection technology;

2. Inspection Sensitivity: Amax = 5 V/G; Sensitivity modulation value: A = 2.6 V/G;

3. Operating magnetic field strength: < 20 MT;

4. Test rope diameter range: 1-200 mm (as defined by specific models);

5. Testing interval differentiation rate: 0.002 m;

6. Rope speed: Vmax = 30 m/sec; controlled rope speed range: V = 0.2-13 m/sec; safety testing rope speed: V < 2 m/sec; inspecting resolution not affected by rope speed;

7. Inspection accuracy: Pmax < 0.05%;

8. Uncertainty for measuring the percentage loss of effective metallic bearing cross-sectional area (LMA): P < 1%;

9. Inspected rope length collating error: C < 10 mm/100 m;

10. Slight defects: detecting capability > 90%

Major defects: detecting capability > 99%

11. Total weight for the testing head unit: standard model ≤ 2KG; advanced model ≤3.6KG

12. Dimension (length, width, and height) for the testing head unit: standard model = 268 x 195 x 172 mm; advanced model = 420x160 x275 mm

13. Wide-space inspection and the gap between the sensor and the surface of the rope: 20-30 mm

14. Temperature range: -30℃ ~ +55℃; No temperature drift

15. Work environment humidity: ≤ 95% RH.

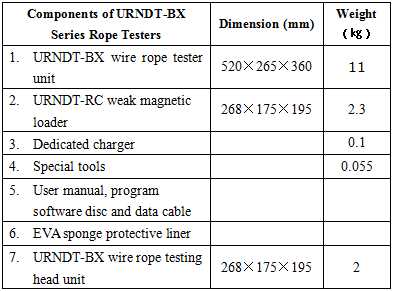

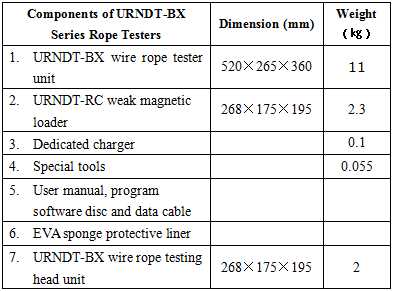

V. Structure and Components

1.Configuration of URNDT-BX Portable Wire Rope Testers (standard model)

2.. Mechanical Structure of URNDT-BX Portable Wire Rope Testers

URNDT-BX portable wire rope testers come with auto-unlocking device, which can self-unlock from the wire rope in emergency situation. The protective caps avoid oil sludge splattering, and the guide wheels at both ends of the tester keep the target wire rope in the center of the tester and also act as buffers for the bouncing and vibration of the wire rope.

3. Function Units of URNDT-BX Portable Wire Rope Testers

1) DC electromagnetic coils;

2) URNDT system self-diagnosis module --- automatically check the system status before inspection;

3) URNDT digital module --- AD/DA signal conversion;

4) URNDT “Eagle Eye” detecting module --- calibrating and signal extracting;

5) URNDT S/N quality module --- signal quality fidelity;

6) URNDT 128 x 128 LCD Display --- real-time display of testing results;

7) Embedded 32-bit industrial CPU --- support 32M data recording, storing, retrieving, processing, converting and displaying;

8) Large capacity program storage system;

9) Large capacity data storage system --- maintaining testing data for 10 years without power supply;

10) Imbedded hardware real-time clock.

VI. Functions of URNDT-BX Portable Wire Rope Testers

1.Quantitatively detecting both external and internal flaws such as broken wires, abrasion, corrosion, fatigue, and

other defects; and correctly evaluating the inspected wire rope’s residual bearing capacity, safety coefficient and

service life;

2..Real time Sound/Light alarm function during the inspection process;

3.Online automatic calibrating technique to ensure the accuracy of inspection results;

4.Self-diagnosis function to ensure the system operate reliably;

5.Quantitatively calculate broken wires in one lay length or 6D/30D length and rope diameter reduction;

6.Integrated design of testing instrument and meters, with no need for external power supply and cable connection;

7.With a working space of 20-30 mm between the testing heads and the wire rope surface and the opposite motion

mode of the guide wheels and wire rope, URNDT portable rope testers have exceptional passing capability,

which is not affected by broken wires, rope deformation, oil sludge, dirt and other factors, and capable of

inspecting under any working conditions;

8.During inspection, the tester’s inner bush will not rub against the wire rope directly and intensively; and it is

designed for permanent use, with no need to replace or maintain.

9.Trigger type self-unlocking device, which quickly unlock the tester from the rope in emergency situation to

ensure the safety of the inspectors and the equipment;

10.Easy for operation because of simple instrument keyboard setting, rolling linear logic interface switch, indicative

man-machine conversation, and embedded intelligent program operation;

11.As soon as an inspection is completed, the inspectors can check the inspection data, flaw curves, analysis

report, and numerical inspection result on the tester’s LCD screen; if the tester is connected to a printer, a

formal test report can be printed out;

12.High performance rechargeable Lithium Polymer battery unit;

13.Testing head employs high strength, insulated anti-corrosive material to prevent electricity leakage, short circuit,

and electric shock by lightning;

14.Quantitative inspection methods and evaluation rules meet the requirements prescribed in MT/T970-2005 Non-

destructive and Quantitative Inspection Methods and Evaluation Rules for Wire Rope and other industries’

standards and requirements;

15.The instrument is CE certified and has no electromagnetic pollution; it does not interfere with the normal

operation of other electronic and communication equipments in the work locale;

16.Water, dust, oil and moisture proof.

VII. Key Features of URNDT-BX Portable Wire Rope Testers

1. High inspecting precision, sensitivity and accuracy:the sensitivity of URNDT Dou Sensors is 70,000 -250,000

times higher than traditional sensors; with high differentiation rate, the Dou sensor is able to inspect

quantitatively all types of wire rope defects;

2. Reliable performance: quantitative uncertainty for measuring the percentage loss of effective bearing metallic

cross-sectional area (LMA) and other flaws such as broken wires, corrosion and abrasion (LF) < 0. 5%;

3. High level integration: all function modules are integrated, including system self-diagnosis module, digital

automatic calibration module, “Eagle Eye” module, S/N quality module, signal fidelity module, and anti-

interference module;

4. Fast data processing capability: by analyzing the original data extracted by URNDT testers from the wire rope,

URNDT patented software is capable of evaluting the working condition of the rope in use. It will not only

display the testing result and print out the test report in real time, but also exchange data between the tester and a

PC at fast speed;

5. Small size and light weight: URNDT-BX standard rope testers weigh less than 2 KG or 1/6~1/20 lighter than

traditional wire rope NDT testing equipments. Therefore, it is very easy to operate;

6. Wide applicability: applicable to wire rope inspections under complex working conditions and not be affected by

the inspectors’ experience or skills, rope speed, noise, water spraying, warped wires, oil dirt and other factors;

7. Accurate inspection results: capable of quantitatively measuring the percentage loss of effective bearing metallic

cross-sectional area (LMA), caused by internal and/or external broken wires, abrasion, corrosion, fatigue and

other defects and thereby evaluate the residual bearing capacity and service life of the inspected wire rope.

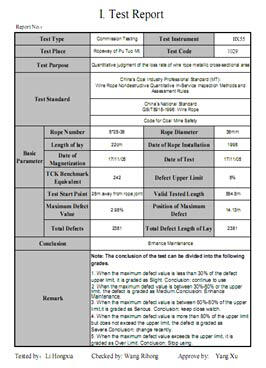

VIII. Analysis Software and Test Report

1. URNDT (Lower Computer) Embedded Inspection Software V 1.2

It is installed in URNDT-BX portable testers and its main functions include calibrating the tester on the target rope (establishing the reference value or standard for inspecting the rope), real-time signal extracting, data storage and processing, data retrieval, memory management and equipment self-diagnosis.

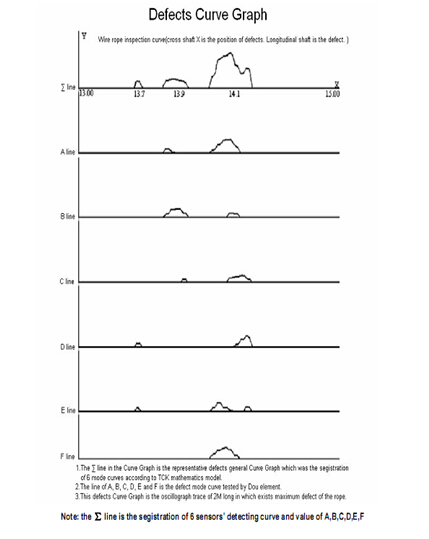

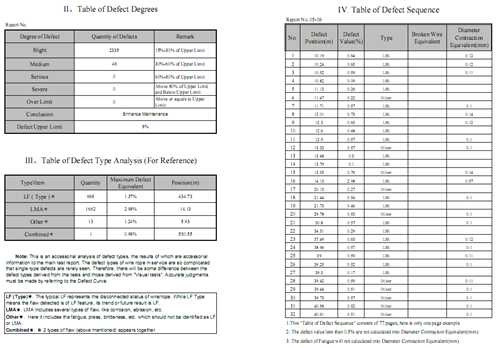

2. URNDT Wire Rope Quantitative Inspection System V3.0 (Upper Computer)

Its main functions include testing data processing, data communication, flaw curve analysis, data table management, data/report displaying and printing, and file management.

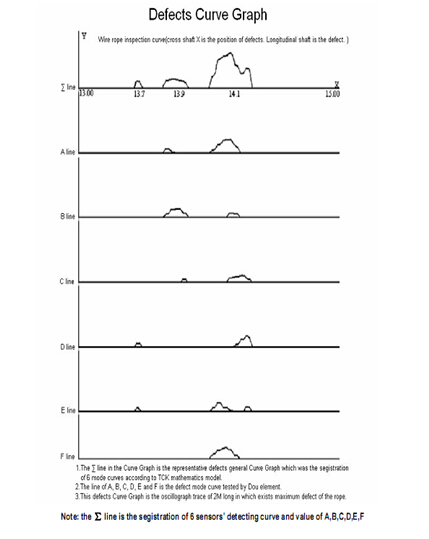

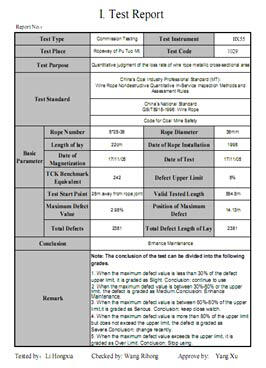

3.Test Report

IX. Applications of URNDT-BX Portable Wire Rope Testers

URNDT-BX portable wire rope testers have been used widely in many industries, such as mining, petroleum, steel plants, heavy equipment manufacturing, ports, transportation, construction, water conservancy, resort, aerospace, and the military. Worldwide, there are over 1,000